Micro Data Center (MDC) products are designed to meet the needs of modern IT infrastructure deployment, to achieve rapid construction and optimized management. MDC adopts an integrated design to package multiple key systems such as rack, uninterrupted power supply, precision cooling, DCIM & local monitoring, and security systems, as a total pre-engineered solution.

MDC products with the above features are becoming the mainstream of the current small-medium data center design & build method.

Comes with all the advantages is the biggest issue we need to be careful, the CONDENSATE.

Cause of Condensate in MDC

One of the core features of MDC is the placement of cooling system inside the cabinet, creating an isolated environment that is independent of external cooling.

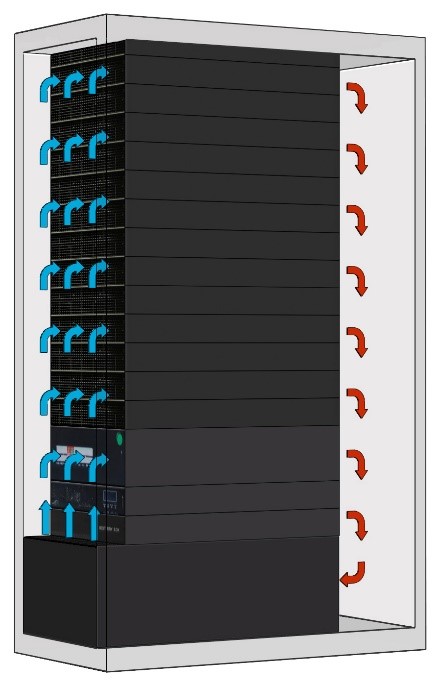

The following figure is a common refrigeration cycle diagram of MDC. The cabinet is fully enclosed and cooled by an air conditioning system. The blue arrow represents the cooling airflow out, and the red arrow represents the cooling airflow return.

Under normal conditions, the air supply temperature should be maintained at 18~27 °C, and the relative humidity is between 30%~80%. When the heat load in the cabinet is much smaller than the rated cooling capacity of the cooling, the cooling system will over-cool the cabinet to a much lower temperature. In this way, the cold air inside MDC may cause water condensate, and things get worse when the MDC does not have an effective seal, or the thermal insulation of the MDC is not enough.

Principles to Avoid Water Condensate of Micro Data Center

Based on this, the design and optimization of the cooling system become very important, otherwise the condensate problem caused by improper air conditioning application will affect the customer’s valuable IT equipments. Generally the condensation problem can be effectively solved by the following method:

- Keep the cabinet seal enough to prevent any moisture coming into the MDC.

- Design with good thermal insulation to prevent any cold-bridge to form condensate on the metal surface of MDC.

- Design the cooling system with adjustable capacity and optimize the cooling & de-humdification logic, so that the AC operation ensures that the temperature & humidity inside the cabinet is within a reasonable range.

- Try to avoid MDC products working in ultra-low load operation.

Anti-condensation design of Attom MDC

As a professional MDC product solution provider, Attom has considered various factors affecting the normal operation of IT equipment at the beginning of design. All Attom Micro Data Centers have adopted the following design and measures to prevent the risk of water condensate.

- Inverter cooling system technology. Attom MDC’s cooling system adopts inverter and EC fan technology, which enable the adjustable capacity from 30% -100% to match the heat load inside the micro data center.

- The thermal insulation design of the cabinet enclosure. The front door glass and the sheet metal part of the cold aisle area are excellently insulated. The front glass door is double insulated glass, and the sheet metal part is covered with insulation cotton to prevent the exterior of the cabinet.

- Careful sealing design, MDC cabinet adopts front and rear door with sealing rubber (waterproof, dustproof and airproof) to effectively prevent air exchange inside and outside the cabinet.

- Utilising electric reheater in the air conditioner to assist humidity control.

- Sealing the wire/piping holes to prevent air moisture leaking.

Don’t forget to contact with our micro data center expert if you have any water condensate problem.

Leave A Comment

You must be logged in to post a comment.