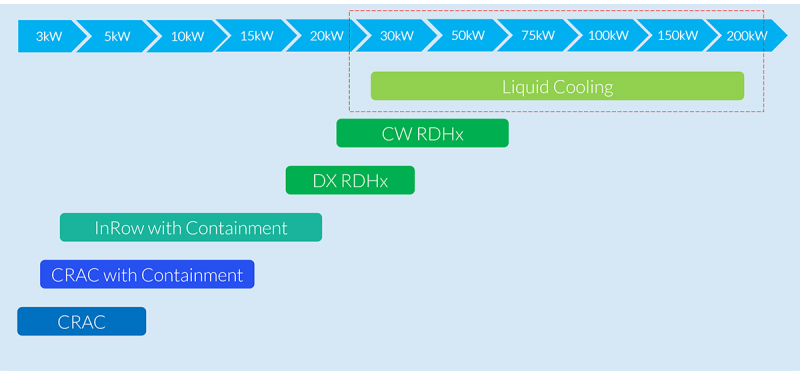

By 2025, liquid cooling has become a mature and reliable technology in modern data centers — especially in AI training, high-performance computing (HPC), and edge computing environments. Once considered experimental, it is now a core element of mainstream infrastructure planning. Many operators are integrating or planning to deploy liquid cooling systems in new data centers to handle higher-density workloads and meet increasingly stringent energy efficiency and sustainability targets.

Liquid Cooling Versus Air Cooling: How Thermal Management Systems Are Evolving

Understanding Liquid Cooling Options and Performance

Water and specialized coolants have roughly 3,000 times the heat-carrying capacity of air. This allows liquid-based systems to move large amounts of heat away from components at much lower flow rates and temperatures. When properly designed, liquid cooling can sustain rack densities beyond what air cooling can handle efficiently — not because every rack runs above 30 kW, but because even small hotspots can be stabilized effectively without redesigning the entire airflow system.

Liquid Cooling Types

-

Direct-to-Chip Cooling (D2C) – Coolant flows through cold plates mounted directly on processors and GPUs. This method is highly efficient and compatible with standard rack formats.

-

Immersion Cooling – Entire servers are submerged in dielectric fluids. This approach minimizes moving parts and supports very high densities, but often requires customized enclosures and handling.

-

Rear Door Heat Exchangers (RDHx) – A transitional solution where liquid-cooled doors remove exhaust heat from air-cooled racks. Effective for gradual upgrades.

Six Key Considerations When Introducing Liquid Cooling into Air-Cooled Data Centers

Accurate Thermal Load Assessment

Before introducing any liquid loop, conduct detailed rack-level power and thermal mapping. Relying on average rack power is insufficient — peak loads and uneven heat distribution define design constraints. Identify high-density racks, measure actual consumption under workload, and model airflow/temperature gradients using CFD tools. This ensures liquid cooling is targeted where it matters most.

Hardware Compatibility and Vendor Coordination

Confirm with server OEMs and component vendors that your cooling method and fittings align with warranty and mechanical specifications. Cold plates, quick-disconnects, and manifolds differ by design. Some vendors restrict third-party cooling modifications, so ensure compatibility and maintain spare part inventories for long-term sustainability.

Infrastructure and Retrofit Feasibility

Integrating liquid cooling into an existing air-cooled hall involves careful facility review: CDU placement, secondary loop routing, pump capacity, floor loading, ceiling clearance, and piping pathways. Each of these influences cost and maintainability. Older facilities might require minor civil modifications to safely accommodate coolant distribution and leak containment.

Leak Prevention and Emergency Preparedness

Even with non-conductive fluids, every design must anticipate failure scenarios. Dual-sealed connections, isolation valves, and inline leak detection sensors are essential. Define emergency response steps, including rapid isolation, containment trays, and power-off sequences. These are mandatory safety measures, not optional features.

Operations and Maintenance Readiness

Liquid cooling introduces new maintenance workflows that differ from traditional air systems. Operators must be trained in fluid handling, connector management, CDU maintenance, and system flushing. Establish preventive maintenance schedules, vendor support SLAs, and local spare part logistics. Effective documentation and regular drills are key to operational reliability.

Cost, TCO, and Phased Deployment Strategy

Liquid cooling isn’t an all-or-nothing transition. Begin with pilot racks or isolated zones to measure performance and ROI before scaling. Analyze both CAPEX and OPEX, including energy savings, water treatment, pump operation, and potential heat recovery benefits. Build a three-year TCO model to guide investment decisions and justify gradual expansion.

Evaluating Liquid Cooling Efficiency

Introducing liquid cooling changes the way efficiency is measured. Traditional PUE (Power Usage Effectiveness) remains a useful indicator but should be complemented with metrics like TUE (Thermal Usage Effectiveness) and CUE (Carbon Usage Effectiveness). In particular, when waste heat is reused, overall facility efficiency can improve even if PUE alone doesn’t drop dramatically.

Confidence in Deployment: Complete Solutions from Attom

Attom provides a comprehensive portfolio of liquid cooling solutions designed for real-world deployment — including direct-to-chip cooling, coolant distribution units (CDUs), and integrated monitoring and safety systems. Our engineering team supports full lifecycle services from thermal assessment to on-site commissioning and training, ensuring every system achieves high reliability, energy savings, and scalability.

Leave A Comment

You must be logged in to post a comment.